AICoolit™ Rack Manifold for Liquid Cooling Solutions

On-Stop Provider for your Swift Critical Cooling Deployment Needs

Core Connection Function & Dual Type Options

Serves as a key component connecting CDU (Cooling Distribution Unit) and cold plates in the main liquid cooling loop, ensuring stable fluid circulation for heat exchange.

Available in single-tube (for quick connect) and double-row tube (for blind connect with welding process) types, adapting to different installation requirements of data center liquid cooling systems.

Ultra-Precision Manufacturing & High Reliability

Adopts ultra-precision manufacturing with position accuracy of ±0.15mm; produced in clean rooms under strict MES control to ensure high cleanliness and dimensional precision.

Passes dual pressure testing (gas and liquid) for high reliability; features strong corrosion resistance and high strength, suitable for both military and civilian high-density data center scenarios.

Excellent Material Performance & Wide Adaptability

Constructed with high-quality SUS304, SUS316L (MDU030S) and SUS304, SUS310L (MDU030D) materials, offering strong corrosion resistance and easy processability for long-term stable operation.

Operates in a wide temperature range of -180℃~-40℃, compatible with ethylene glycol, propylene glycol, deionized water and other common liquid cooling media.

Uniform Flow Distribution & Flexible Installation

Optimized internal structure ensures uniform flow distribution, improving overall heat exchange efficiency of the liquid cooling system.

Offers optional self-fastening and blind connection types; available in 30X30, 40X40, 50X50 mm specifications to meet diverse project requirements.

Position accuracy of ±0.15mm ensures perfect fit with other components; strict MES control and clean room production guarantee product consistency.

Dual pressure testing (gas & liquid) eliminates leakage risks; corrosion-resistant materials adapt to harsh liquid cooling environments for long service life.

Dual connection types (quick connect/blind connect) and multiple specifications meet diverse installation needs; compatible with common liquid cooling media.

Uniform flow distribution optimizes heat transfer efficiency; stable fluid circulation ensures reliable cooling performance for high-density data centers.

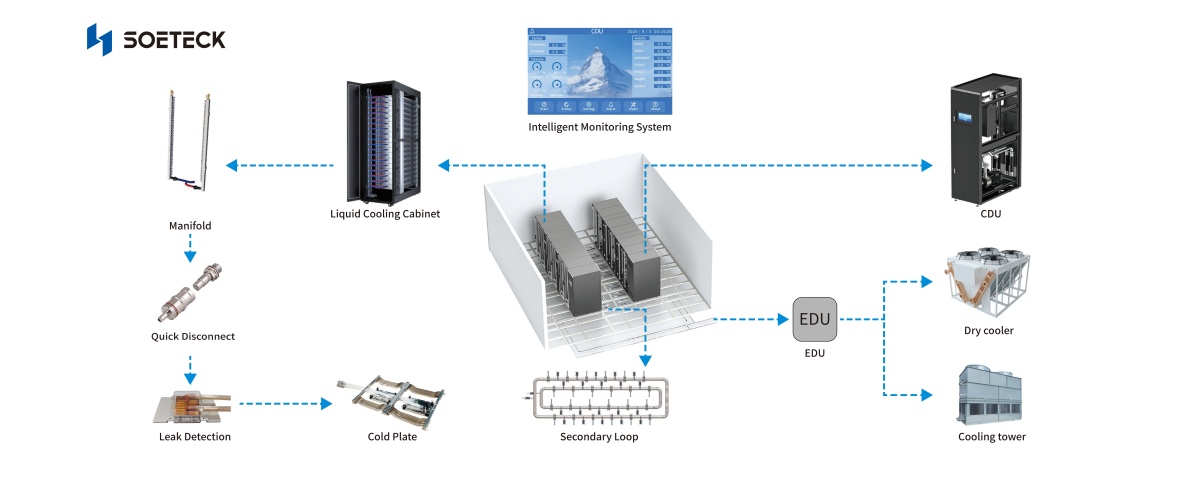

Soeteck delivers a full-chain cold plate liquid cooling solution, highlighting high-efficiency heat exchange, intelligent operation and maintenance, and outstanding reliability. The solution encompasses liquid cooling cabinets, cold plates, secondary loops, CDU, dry coolers, and cooling towers. Beyond core products, we offer reliable OEM/ODM customization, fast delivery, a professional technical team, hassle-free after-sales support, and remote technical assistance.

Focus on the core cooling demands of high-density data center deployments, where our full range of premium products leverages advanced technological advantages to reliably safeguard continuous, efficient, and stable operation.

1-80 kW

High thermal conductivity, compact footprint, direct heat transfer, ideal for high-power electronic components.

10-80 kW

Uniform temperature control, zero dust intrusion, ideal for high-density data centers & supercomputers.

21.2-31.1 kW

No server room reconstruction, high heat rejection efficiency, plug-and-play installation, fits existing rack infrastructure.

20-1600 kW

Redundant fan design, low noise level, adjustable airflow, perfect for data centers & industrial cooling facilities.

|

• High-Density Data Centers (IDC) • Military Electronic Equipment Cooling Systems • Civilian High-Power Electronic Component Cooling • Cold Plate Liquid Cooling Systems • Precision Electronic Equipment Cooling • Industrial Control System Liquid Cooling • Supercomputing Center Cooling Systems • Telecommunication Base Station High-Power Equipment Cooling |

|